As FPE Automation Enters its 60th Year, Here is a Look Back

FPE Automation Celebrates Sixtieth Anniversary in 2023

By Sandia Harrison, Director of Marketing

It All Started with A Couple of Guys from Michigan… and MAC Valves

The year is 1963. John F. Kennedy is President of the United States, “She Loves You” by the Beatles is the #1 hit of the day, and Martin Luther King delivers his famous “I have a dream” speech.

Meanwhile, in Michigan, the management at MAC Valves, a manufacturer of premier air valves, is having a hard time finding a Chicago-area distributor. It’s a key market for anyone in industrial automation. The Midwestern United States was a manufacturing hub then, and remains so today.

Unable to find suitable representation to cover this important territory, the executives at MAC turn to two young, star employees.

Do You Want to Move to Chicago?

They offer Dick Bardos and Jim Murphy something that would end up being the opportunity of a lifetime. "Take your wife and kids, move to Illinois, and set up shop as the MAC Valves distributor there."

It all started in the Bardos’ family garage. Weeks later, Dick and Jim locate a facility with both office space and warehouse space. They name the company “Fluid Power Engineering”, or “FPE” for short.

|

| FPE in the 1960s and 1980s |

An Ideal Balance

In many ways, Dick and Jim are opposites. Dick is a morning person, brilliantly intelligent, with a wry smile and loads of charm. Jim prefers to get to work around 9:30. He’s a natural salesperson, with a big personality and a sense of humor. Both are men of integrity and the utmost honesty. It’s both their differences and their similarities that made FPE a success. Together, they get to work, building FPE. Over the decades, they nurture the company with their talented direction as it becomes an industry leader in the region it serves. From the largest companies in the area to one-person job shops, and across numerous industries, the FPE team develops longstanding and strong bonds with them all.

A Life Dedicated to Industrial Automation

It is not long before FPE begins winning top industry awards for performance and breaking records for sales. With the company’s stellar reputation for honesty and excellent customer service, soon many other suppliers want FPE to be their distributor too. FPE’s line card grows, and the industry accolades continue to come in.

|

| Dick Bardos (left) and Jim Murphy |

Eventually, Jim retires. After many golden years filled with sailing and other endeavors, Jim passes away peacefully at home in 2009, around a month prior to his 90th birthday.

Upon Jim’s retirement, Dick takes over his share of the business to become the sole owner and CEO. Having a true passion for his life’s work, Dick never fully steps away from the company he cares so much about. Instead, he eventually takes on a more advisory role, while his son David, who has been in the business for some years at this point, steps up as the new President of FPE. Dick’s daughter Lori, who was working as CPA at an accounting firm at the time, assumes the role of Vice President and Controller. As the two begin to oversee everyday operations, Dick and his lovely wife Ruthe split their time between Naples, Florida and their home in Illinois. They enjoy an active life filled with golf, family, and friends, until Dick sadly passes away in 2013 at the age of 81.

New Generations of Leadership

The years that follow are some of FPE’s most pivotal ones. Industrial automation is changing. The industrial climate is tumultuous. Offshore products & cheap knockoffs are threatening American manufacturing in new ways. Inflation, 9/11, the global financial crisis of 2008, rising prices, shrinking profit margins…

Had David Bardos been a different sort of individual, it all would have been too much.

David is a no-nonsense, highly creative guy. A sharp dresser, extremely likable, with a true gift for gab. At a crowded and noisy table, if Dave starts telling a story, soon everyone is listening intently. His smooth, unassuming and often self-deprecating style is attention-grabbing. When Dave walks into a room, somehow everyone is immediately at ease.

David would have his own vision of how FPE would take shape in the years to come.

In 2004, FPE opens an office in Sunset Hills, Missouri. The company’s territory expands to include the entire state of Illinois, the Quad Cities, Iowa area, and the greater St. Louis/eastern Missouri region.

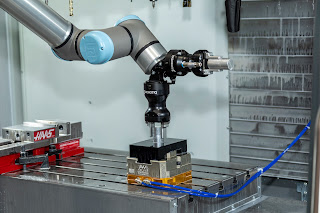

One key initiative, in particular, stands out as exceptionally pivotal during this time. Dave recognizes that industry is headed in the direction of increased automation controls. Although MAC Valves still remains FPE’s top product line, Dave adds an Automation Controls Division (ACD). FPE is an early adopter; many don't enter into controls until years later. In 2015, Dave changes the company name from “Fluid Power Engineering” to “FPE Automation” to reflect FPE’s commitment to all types of industrial components. Today, our Automation Controls Division is one of the finest in the region, with a team of highly-skilled application engineers who make industrial robotics and artificial intelligence (AI) a reality at companies large and small.

Part of a Bigger Picture

FPE Automation is shaped as much over the years by its customers and global events as it is by its leadership. Workplace safety, shortages of skilled labor, COVID, and supply chain issues have forced customers to do more with less.

As FPE Automation continues to develop expertise in key areas, it becomes apparent that they need to share that expertise with businesses in the region. Even as automation enters the mainstream, companies still struggle to implement it. At the same time, they realize that they can’t afford not to do so.

By this time, David’s son, Joey Bardos has been climbing the ranks at FPE. Experienced in several roles, in 2021, Joey takes the reins as FPE Automation’s new president. David assumes the role of CEO. A third generation proudly enters into the family business. Joey is bright, energetic, and highly motivated. Very focused on growth and sustainability. He has an excellent understanding of where things are headed and cares deeply about FPE Automation. Joey will make absolutely sure the company is where it needs to be.

In his first announcement as president, Joey says, “I am looking forward to building off our strong foundation and taking FPE to the next level with the strong team we have."

|

| Left to Right: Joey Bardos, Lori Wolff, David Bardos |

Change is Inevitable, Growth is Optional

COVID finally begins to subside. Automation has now taken hold. In February of 2021, Forbes notes that “The advantage [of automation] is huge and old-school businesses that have not embraced automation have fallen behind quickly.”

Businesses are concerned about remaining relevant in today’s market. They begin asking FPE Automation to help them to automate. Joey quickly realizes the weight of those requests. Engineering teams don’t have the time or internal expertise to get the projects done. However, they can’t remain competitive unless they produce their goods more intelligently. There is a genuine need for FPE Automation to expand its scope. It’s a make-or-break decision for many of our customers.

Under Joey’s leadership, FPE Automation's Handshake Solutions division is created. The concept is simple. Bring us your automation project. We’ll either help you handle it, tackle it with you, or bring in a certified systems integrator (CSI) to do the job. The Handshake Solutions division is an instant success.

Joey also shares the same commitment to offering only the best quality products as the generations before him. He works with the FPE team to foster relationships with new product manufacturers. The result is groundbreaking. FPE is automating tasks that could have only been imagined just a few short years ago. The company’s founders, Dick and Jim, would be proud.

The Future of FPE Automation

We enter our 60th year with four locations and an ever-growing team of experts. What has not changed is the quality of our people. Simply put, they’re the best in the business.

At FPE Automation, we like to say that we “live and work in the community we serve”. Midwestern in our roots since day one, the health of manufacturing here is personal to us.

We look forward to many more years of serving you, our community.