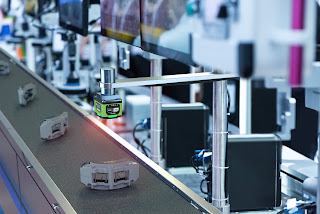

New Devices Are Revolutionizing Fixed Scanning and Machine Vision

With demand for manufacturing production, quality, and supply chain performance at all-time highs, there’s some good news on the way with a big change in the world of industrial automation.

More than ever, companies need to boost high-quality output

and do it as efficiently as possible, with minimal labor. Thankfully, it’s getting

a lot easier due to a major shift in fixed scanning and machine vision

technology.

However, there’s often been one major obstacle to realizing

the benefits of fixed scanning and machine vision, and that’s complexity.

But all of that is changing with Zebra’s entry into the fixed scanning and machine vision industry with a groundbreaking new approach to these technologies. And at FPE Automation, we’re thrilled to be partnering with Zebra to bring this streamlined solution to industrial operations across North America.

As a global leader in barcoding, data capture, identification, and sensor technologies since 1969, Zebra has developed an unparalleled reputation in helping companies automate more processes and increase supply chain traceability, quality, and visibility. But recently Zebra turned its sights to fixed industrial scanning and machine vision, working with leading manufacturers and technology partners to develop a better way to do both.

The end result is Zebra's new singular hardware and software platform for both fixed scanning and machine vision, which offers the easiest setup and integration of any solution on the market. And its powerful data capture and vision-enabled capabilities are poised to compete with the leaders of the industrial automation industry.

Our team at FPE Automation has been working with Zebra on rolling out this exciting new family of solutions, and we’re already working with our clients to help them take advantage of Zebra's game-changing innovation in their automation and inspection jobs.

The first big difference with Zebra's new hardware is that it can deliver either fixed scanning or machine vision from the same device. In fact, you can start with a fixed scanner, such as Zebra's FS20 or FS40, and later unlock its machine vision sensing capabilities with a simple software license upgrade.

Speaking of software, you can set up and configure jobs with these devices using a single software application. Zebra's Aurora software provides all the tools, settings, and guided tutorials you need to set up even the most sophisticated fixed scanning or machine vision jobs—all in a simple, user-friendly, and modern interface.

All settings and configurations can be modified with sliders and radio buttons, and you get access to image auto-tuning and other features to simplify setup, along with guided tutorials and videos to help you learn as you go.

For example, with Zebra's Object Locate, you can rapidly and accurately locate objects right out of the box with optimized settings, regardless of orientation, position, or other variances. With its QuickDraw feature, you can draw a box around the area you want to inspect, right on the image, and then choose and configure your preferred image capture tool.This means beginners can get a fixed scanning or machine vision job up and running quickly. But experts can also easily access all the powerful analysis tools and settings they need, including filters, polarizers, pattern recognition, edge detection, pixel counting, a blogs tool, and much more.

Another big advantage of Zebra's hardware is that you can capture up to 16 different images of a single target, each with its own image settings. You can conduct more inspections and scan and check more data with fewer devices. There are multiple exposure settings for targets that require different lighting, and there are multiple focus plane settings for objects at different distances.

In addition, Zebra supports all the lensing and optics options you might need, including liquid lenses; C-mount lenses; internal lighting with blue, white, red, infrared (IR) or multi-color; and external lighting options including front, back, and low-angle illumination.

Zebra's devices also provide dual-Ethernet connectivity, so you can send instructions to your devices through one Ethernet connection and send images for cloud storage, sharing, and analysis with the other. You can connect to virtually any network, system, or hardware device with industry standard protocols including TCP/IP, Serial, Profinet/Modbus, and CC Link.

Additionally, since Zebra's devices also have USB-C connectivity, you can output your results directly to a display monitor, without having to buy and set up a separate industrial PC for this purpose.

If all of this sounds a bit overwhelming, don’t worry. We have experts at FPE Automation who can guide you to the right solutions and help you set up your jobs with all the right tools, settings, and hardware for the results you need.

Plus, with the simplicity of one hardware and software platform to learn and use, and the ability to capture more data and images with less setup time and fewer devices, Zebra's fixed scanning and machine vision solutions will help you learn and get up to speed faster. You can quickly start to set up and configure jobs without outside assistance or support. But, if you need it, we’re still there to help.

For companies that need a simpler, easier, and more affordable way to automate data-driven or image-based production and quality assurance processes, Zebra's new technologies are the solution.

To learn more about Zebra's revolutionary new approach to fixed scanning and machine vision, download this brochure to learn more about these devices and Zebra's Aurora software. Also, feel free to connect with the industrial automation experts at FPE Automation to get more details and answers to your questions.

About FPE Automation

As leaders in industrial automation since 1963, FPE Automation has decades of extensive and proven experience in helping companies automate more processes, boost quality output, and gain a competitive edge through the power of technology. Visit us now to learn how we can help your business.